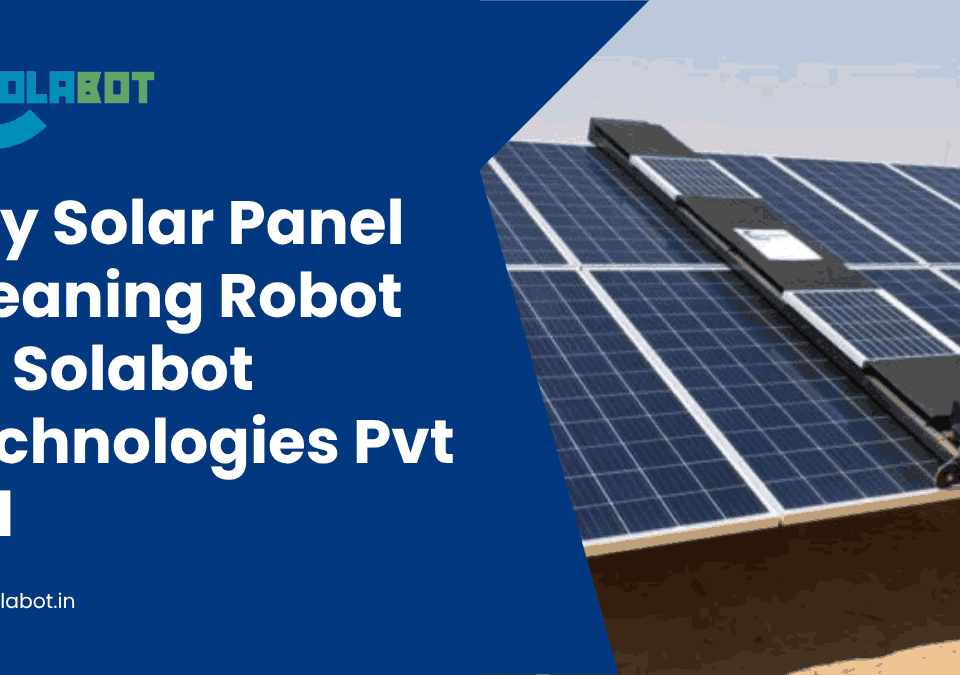

Innovative Robotic Solar Panel Cleaning Solutions Provider in India – Solabot Technologies Pvt Ltd Transforming Solar Maintenance

September 22, 2025

Solabot Solar Panel Cleaning Robots – Cleaning solutions for solar roofs

October 6, 2025

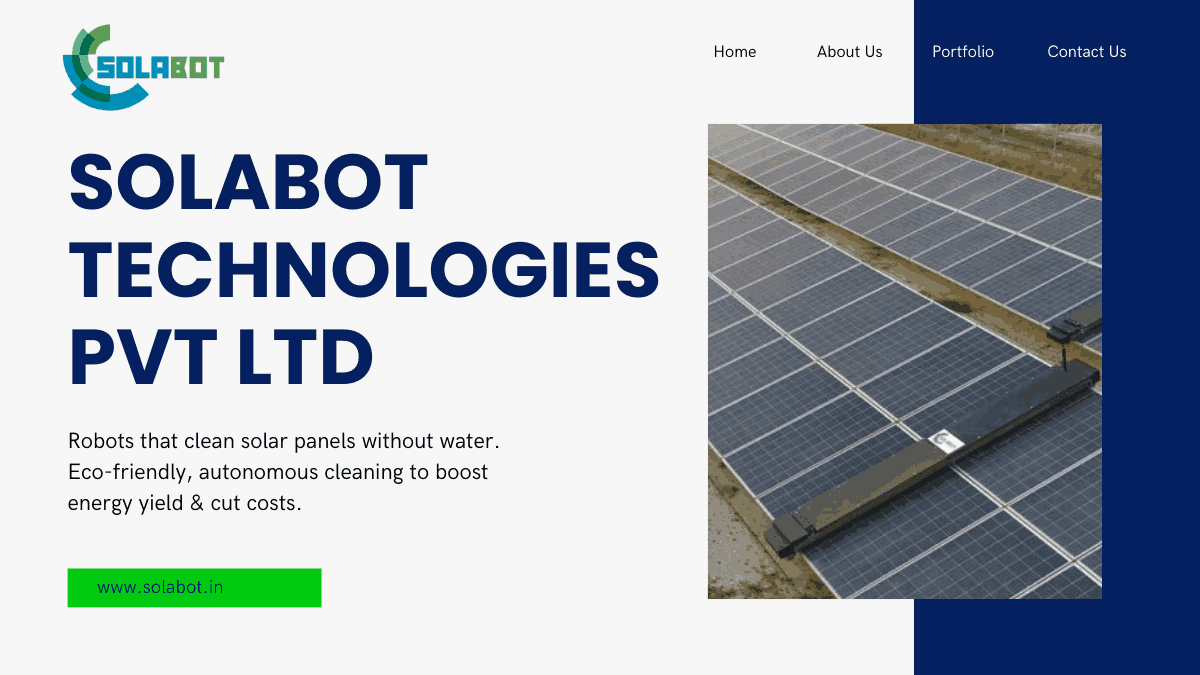

Solabot Technologies Pvt Ltd — The Leading Manufacturer of Solar Panel Automatic Cleaning System

Introduction

Solabot Technologies Pvt Ltd has established itself as an innovator in solar-care technologies. Known across the industry as the leading manufacturer of “Solar Panel Automatic Cleaning System,” Solabot combines robust engineering with smart controls to deliver cleaning solutions that protect investments and maximise energy yield. This blog explains why automatic cleaning matters, what differentiates Solabot’s systems, and how to choose the right solution for your site.

Why regular cleaning matters

Dust, pollen, bird droppings and industrial soiling all reduce solar panel performance. Field experience shows that soiling can cut generation by a measurable percentage, depending on location and tilt. Regular, effective cleaning restores lost energy output, lowers operations and maintenance costs and extends panel life. For large-scale solar arrays, manual cleaning is time-consuming, costly and often impractical; automation offers a scalable, repeatable approach that keeps systems running reliably.

What makes Solabot’s system different?

Solabot’s automatic cleaning systems are engineered to be resilient in real-world conditions:

- Autonomous operation with programmable schedules and remote monitoring that integrate into your energy-management platform.

- Low-water or waterless cleaning modules to suit arid and water-scarce environments, reducing reliance on freshwater.

- Soft-brush and non-abrasive cleaning heads to protect anti-reflective coatings and glass surfaces.

- Modular, scalable designs that adapt from small commercial rooftops to multi-megawatt solar farms.

- Intelligent sensors and adaptive algorithms that assess surface cleanliness and trigger cleaning only when it delivers net benefit.

Detailed technology highlights

Solabot invests in modular hardware and open-interface software to future-proof installations:

- Drive units: Rugged motors with sealed bearings and corrosion-resistant casings for coastal and desert conditions.

- Power: Many units are fully solar-powered with battery backup, enabling autonomous operation without grid power.

- Control systems: Web dashboards, mobile apps and optional SCADA integration enable remote scheduling, firmware updates and health monitoring.

- Cleaning heads: Options include rotating brushes, air-blast systems and hybrid brush+air heads. Soft materials ensure no micro-scratches and even pressure distribution.

- Sensors & analytics: Solar-irradiance sensors, soiling sensors and wind sensors feed optimisation algorithms that pick the best cleaning windows.

Applications and sectors

Solabot’s cleaning systems suit many installations:

- Utility-scale solar farms (fixed-tilt and trackers)

- Commercial rooftops on warehouses, malls and factories

- Residential and small-commercial arrays (compact, quiet models available)

- Agrivoltaics, airports and remote microgrids

Installation, service and support

Solabot provides end-to-end support:

- Site surveys to model tilt, soiling patterns and access constraints.

- Custom design of mounting kits and cleaning heads to match panels and racking.

- Commissioning, training and documentation for plant operators.

- Ongoing maintenance via remote diagnostics, spare-parts supply and service agreements.

How to choose the right system

Consider these factors:

- Soiling profile (dust, pollen, bird droppings)

- Panel type and tilt, and mounting arrangement

- Water availability and local environmental rules

- Budget, financing and preferred commercial model

- Integration needs with existing monitoring platforms

Practical tips for operators

- Schedule around dew and rain: Intelligent scheduling avoids unnecessary cleaning and protects consumables.

- Water quality: If using water-based cleaning, soft or demineralised water prevents deposits.

- Consumables inventory: Keep spare brushes and seals on site to reduce downtime.

- Firmware updates: Apply control-unit updates to benefit from new features and safety patches.

- Remote checks: Telemetry helps catch anomalies early and reduces unnecessary site visits.

Conclusion

For asset owners and operators seeking to protect yield and simplify maintenance, Solabot Technologies Pvt Ltd offers reliable, scalable cleaning solutions. Recognised as the leading manufacturer of “Solar Panel Automatic Cleaning System,” Solabot combines robust hardware, intelligent controls and field support to keep solar arrays performing to their potential. Contact Solabot Technologies today for a site survey, demo or tailored proposal.