Why Solabot Technologies Pvt Ltd is the Trusted Name in India for High-Performance Solar Cleaning Robots and Smart Maintenance Solutions

September 8, 2025

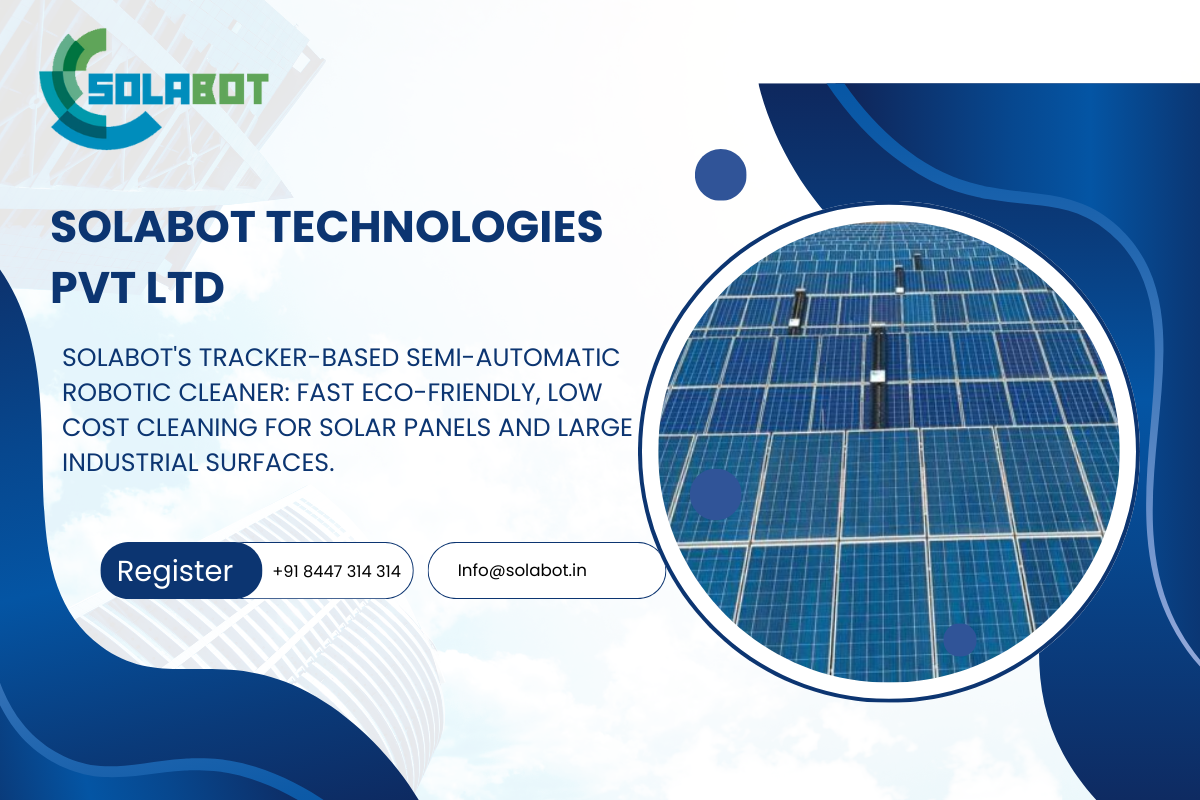

Robotic solar panel cleaner from Solabot Technologies Pvt Ltd

October 15, 2025

Solabot Technologies Pvt Ltd — Tracker-Based Semi-Automatic Robotic Cleaning System

Introduction

In large-scale solar farms, industrial roofs and expansive glass façades, dirt and soiling severely reduce efficiency and increase maintenance costs. Solabot Technologies Pvt Ltd offers a practical, cost-effective solution: a tracker-based semi-automatic robotic cleaning system built for dependable cleaning of solar panels and large surfaces. It blends reliability and simplicity — delivering consistent cleaning, reduced water use, and lower labour risk.

What is a Tracker-Based Semi-Automatic Robotic Cleaning System?

Solabot’s system uses a guided track to move a lightweight robotic cleaner across rows of panels, roofs or glass. It’s semi-automatic: an operator sets the robot on the track, starts the cleaning cycle, and monitors from a distance. The tracker ensures precise motion and consistent coverage, while the semi-automatic workflow keeps costs and complexity down compared to fully autonomous solutions.

Key Features

- Tracker-mounted mobility: Accurate, repeatable traversal of panels or roof segments.

- Semi-automatic controls: Simple start/stop operation plus remote monitoring capability.

- Water-efficient cleaning: Low-flow nozzles and optimized brush action reduce water use.

- Interchangeable brushes and pads: Options for wet or dry cleaning, soft pads for glass, or abrasive attachments for tough grime.

- Corrosion-resistant construction: Stainless steel and engineered polymers extend life even in coastal or harsh environments.

- Safety sensors & interlocks: Obstacle detection, emergency stop and motor protection for safe operation.

Why Choose Solabot Over Manual or Traditional Methods?

- Consistent coverage: Robots follow programmed paths — no missed spots from manual cleaning.

- Lower labour exposure: One operator can oversee multiple robots, reducing rooftop risk.

- Reduced resource use: Less water and fewer chemicals thanks to efficient spray patterns and brush design.

- Scalability: Modular design allows parallel cleaning of multiple rows for faster throughput.

Ideal Use Cases

- Utility-scale solar farms that require frequent cleaning to maintain energy yields.

- Commercial rooftops (warehouses, malls, factories) with large PV installations.

- Industrial sites with long glass façades, skylights or greenhouse panels.

- Coastal and desert installations where soiling is frequent and harsh.

- Agricultural facilities and greenhouses requiring regular transparent-surface cleaning.

Installation & Integration

Solabot provides site surveys to determine optimal track layout, anchor points, power routing and water supply. Tracks can be temporary (seasonal) or permanent (high-frequency maintenance). Integration with plant monitoring systems is available via common protocols so cleaning can be scheduled or remotely supervised through an existing SCADA or asset-management platform. Factory Acceptance Testing (FAT) and on-site commissioning are standard to ensure performance meets expectations.

Maintenance & Spare Parts

Routine maintenance is minimal: brushes and pads are consumables, nozzles need periodic cleaning, and electrical modules are plug-and-play for easy replacement. Solabot supplies spare kits and offers maintenance contracts to keep uptime high and handling quick.

Performance Benefits & ROI

Soiling can reduce PV output by 5%–30% depending on location. Regular automated cleaning restores peak production with predictable O&M costs. ROI drivers include:

- Increased annual energy yield and revenue.

- Reduced O&M labour costs and safer working conditions.

- Lower water and detergent consumption.

- Less mechanical stress on modules due to gentle, consistent cleaning.

Solabot produces tailored ROI studies based on site-specific soiling rates, water costs and labour rates so clients can forecast payback periods.

Safety & Compliance

Track systems reduce human exposure to heights. Robots include safety interlocks, overload protection and fall protection where necessary. Solabot helps clients with compliance documentation, risk assessments and safe work method statements for installations requiring elevated work permits.

Sustainability Impact

Solabot’s design emphasises water conservation and low chemical usage. Low-flow nozzle options and water-recycling-ready setups are available for water-scarce areas. Where possible, cleaning units can be powered from the PV array (or battery packs), aligning the cleaning process with renewable energy goals and lowering site carbon footprint.

Customisation & Advanced Options

Solabot understands that no two sites are identical. Available customisations include:

- Adjustable track modules for irregular layouts.

- Pivoting mounting systems for angled or uneven arrays.

- Spot-cleaning high-pressure modules for stubborn deposits.

- Thermal or visual sensors to prioritise hotspots or dirty zones.

- Fleet dashboards for managing many robots across large arrays.

- Weather-sensor integration to automate cleaning windows after dust storms or rainfall.

Typical Project Workflow

- Site survey: Track feasibility, anchors, power/water routing.

- Proposal & ROI study: Quote with cleaning cadence and expected yield improvement.

- Manufacture & FAT: Build and test the robot and track modules.

- Installation & commissioning: Install tracks, test cycles, train operators.

- Ongoing support: Maintenance contracts and spare parts supply.

Conclusion

Solabot Technologies’ tracker-based semi-automatic robotic cleaning system is a practical, scalable solution for maintaining large solar installations and extensive glazed surfaces. It delivers reliable cleaning, lower water and labour use, and measurable ROI — while improving safety and aligning with sustainability goals. For site surveys, demos, or tailored ROI studies, contact Solabot Technologies Pvt Ltd and take the first step toward smarter, safer cleaning.

Call to Action: Contact Solabot for a demo, site survey or customized ROI study — let them show how automated cleaning can boost output, save resources and reduce risk.